3D printing, also known as additive manufacturing, has moved from niche technology to a mainstream process used to create everything from prototypes and custom parts to functional objects like meat alternatives, medical implants, and even entire houses. Once a futuristic concept, machines are now available for under $200, making the technology accessible to hobbyists and professionals alike. But how does it work, and why is it becoming so essential?

From Subtractive to Additive Manufacturing

Traditional manufacturing often involves subtractive methods – starting with a block of material and removing what isn’t needed. 3D printing flips this around. Instead of wasting material, it builds objects layer by layer, reducing waste and enabling the creation of incredibly complex geometries.

“Mass manufacturing methods are rigid,” explains Diana Haidar, a mechanical engineering professor at Carnegie Mellon University. “You remake the same parts repeatedly. 3D printing unlocks customization – building unique parts on demand.”

The Core Principle: Layer-by-Layer Construction

At its heart, 3D printing takes a digital 3D model and slices it into countless horizontal layers. The printer then builds the object by depositing material one layer at a time. This process relies on a “z-axis” change – either the printing head moves up or the build platform drops to accommodate each new layer.

Popular 3D Printing Methods

There are several dominant 3D printing techniques, each suited for different materials and applications:

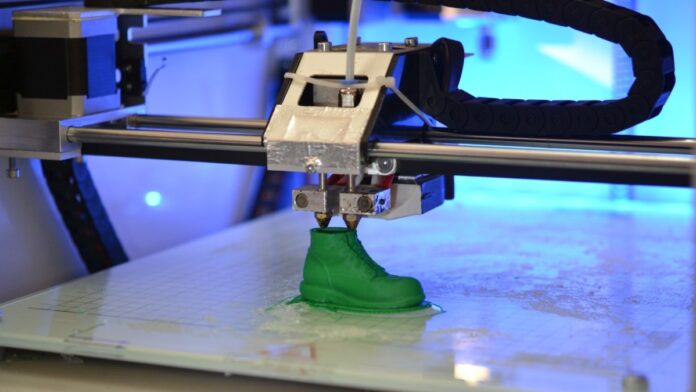

Fused Deposition Modeling (FDM)

This is the most common method, especially for beginners. FDM uses a spool of filament (typically plastic or polymer) fed into a heated nozzle. The material melts and is extruded onto the build platform, solidifying as it cools. Polylactic acid (PLA) is a popular material due to its low melting point and affordability. Higher resolution prints are achieved with smaller nozzles.

Stereolithography (SLA)

SLA employs a liquid resin cured by a UV laser. The process involves a tank of uncured resin, where the laser solidifies each layer. Once cured, the layer separates from the bottom of the tank and rises, eventually forming the complete object. SLA is known for its precision but requires handling liquid resins.

Laser Powder Bed Fusion

This technique is ideal for metals. A laser selectively melts powdered metal particles on a flat bed, fusing them together layer by layer. After each layer, a roller distributes fresh powder, and the process repeats. This method is used for high-strength parts in aerospace, medical, and automotive industries.

Bio-Printing

For specialized applications like organ printing, machines inject different types of cells into a hydrogel matrix instead of using filaments or resins. This allows for the creation of complex biological structures.

Cost and Trade-offs

The price of 3D printers varies widely:

- Entry-Level ($200): Affordable but often less reliable, with inconsistent results. Temperature control issues can warp materials.

- Mid-Range Desktop ($3,000): More consistent and includes software packages.

- High-End Manufacturing ($200,000): Offers professional-grade durability and precision.

- Metal 3D Printers ($1 Million): Requires specialized, controlled environments to prevent explosions and maintain material integrity.

Investing in higher-end machines reduces maintenance costs and enables printing with more challenging materials.

In conclusion, 3D printing is a transformative technology that’s evolving rapidly. From its core principle of layer-by-layer construction to the diverse methods available, it’s reshaping manufacturing, prototyping, and even bio-engineering. As costs continue to fall and capabilities expand, 3D printing will become even more integral to innovation across industries.